Cooking changes meat from its raw state into a finished masterpiece worthy of being at the center of a meal. But how and why does the application of heat cause changes in meat? To answer this question you need to know exactly what muscle fibers are, and what’s going on inside them at specific temperatures. Understanding how protein fibers change during cooking will improve the quality of meat you cook!

How Temperature Affects Meat

Determining the doneness temperature of meat is important for two main reasons:

- Food Safety It’s important that all possible foodborne pathogens are denatured before any meat is served. Professional cooks at restaurants know this fact well. Government regulations for sanitation and food safe doneness temperatures are in place to ensure public safety. For both USDA recommended doneness temperatures for food safety and chef recommended doneness temperatures, see the Chef Recommended Temperature Chart in our Learning Center.

- Food Quality Eating quality of food is a subjective evaluation of texture, flavor, and general mouthfeel (sensation in the mouth determined by such factors as moisture, richness, astringency, and temperature).

What are Muscles Made Of?

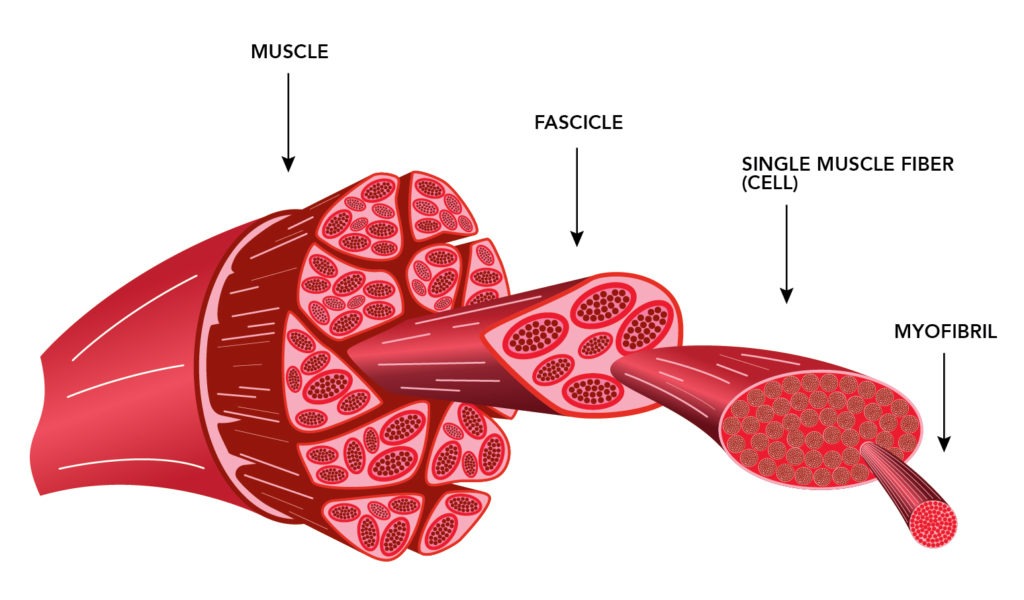

We often hear talk of muscle fibers and the “grain” of meat. Muscle fibers are long protein fiber strands and the direction of their formation is the grain of the meat (pictured right). Muscle meat of land animals is made up of many bundles of protein fibers. These bundles of protein fibers are called fascicles. Each muscle fiber is a multinucleated cell is made up of bundles of myofibrils. Each myofibril is made up of thousands of sarcomeres (contractile units) that are composed of myofilaments. And it’s inside these sarcomeres where all the activity of contraction takes place in muscles. This is the general muscle structure found in beef, pork, lamb, and poultry.

We often hear talk of muscle fibers and the “grain” of meat. Muscle fibers are long protein fiber strands and the direction of their formation is the grain of the meat (pictured right). Muscle meat of land animals is made up of many bundles of protein fibers. These bundles of protein fibers are called fascicles. Each muscle fiber is a multinucleated cell is made up of bundles of myofibrils. Each myofibril is made up of thousands of sarcomeres (contractile units) that are composed of myofilaments. And it’s inside these sarcomeres where all the activity of contraction takes place in muscles. This is the general muscle structure found in beef, pork, lamb, and poultry.

Why We Cook Meat

We are more highly evolved than our primitive ancestors who hunted and ate raw meat for survival. We eat for nutrition and pleasure. Cooking meat causes chemical changes that make it easier to chew and transform it into a mouthwatering culinary experience.

Specific chemical reactions occur in meat at distinct temperatures regardless of the cooking method used. Knowing what those temperature landmarks are and using precision temperature tools to determine doneness are they keys to becoming a meat cooking master! Some of the changes we can easily see when cooking meat are in:

- Opacity—The once translucent meat becomes opaque.

- Firmness—Meat can be tender or tough.

- Shrinking—Cuts of meat shrink in size as they approach doneness.

- Browning—The meat changes color from pink to gray/brown. Seared meat develops a deeply-colored crust.

- Moisture Loss—Liquid is expelled as the meat becomes more firm.

- Fat Breakdown—Intramuscular fat dissolves in the temperature range of 125-130°F (52-54°C), giving meat a succulent mouthfeel.

Color Changes

Myoglobin in meat is what gives it its pink/red hue. Myoglobin denaturation is responsible for the color change between raw and cooked meat. This change occurs at 140°F (60°C).

Opacity

When protein molecules denature, their coiled structure unfolds. These unfolded molecules then bump into each other and reconnect in a different configuration (coagulate), making it nearly impossible for light to pass through. This is what turns meat from translucent to opaque.

Moisture Loss

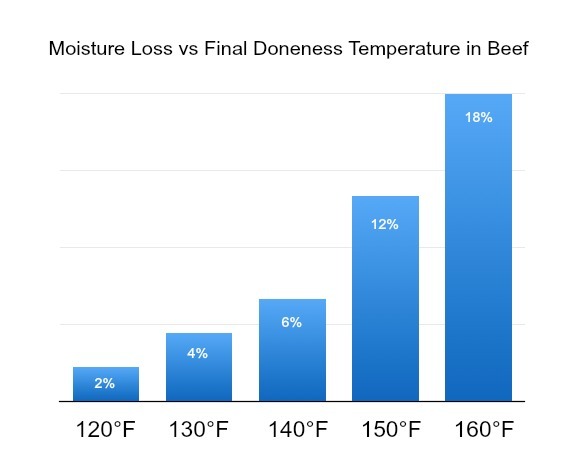

Juiciness is a considerable factor in determining the final eating quality of cooked meat. No matter how long it’s brined, marinated, or even if it’s cooked in liquid, moisture loss in meat is directly related to its final doneness temperature. Kenji Lopez-Alt has conducted his own research and found that the amount of moisture lost in meat increases dramatically once its internal temperature reaches 150°F (66°C). See the findings of Kenji’s research in the chart below (from The Food Lab, by J. Kenji Lopez-Alt):

The effects of shrinking and firmness are what drive moisture loss in meat, and are directly related to subcellular changes that occur in the protein fibers during cooking. What happens that causes such a striking change?

Myosin and Actin in Muscles

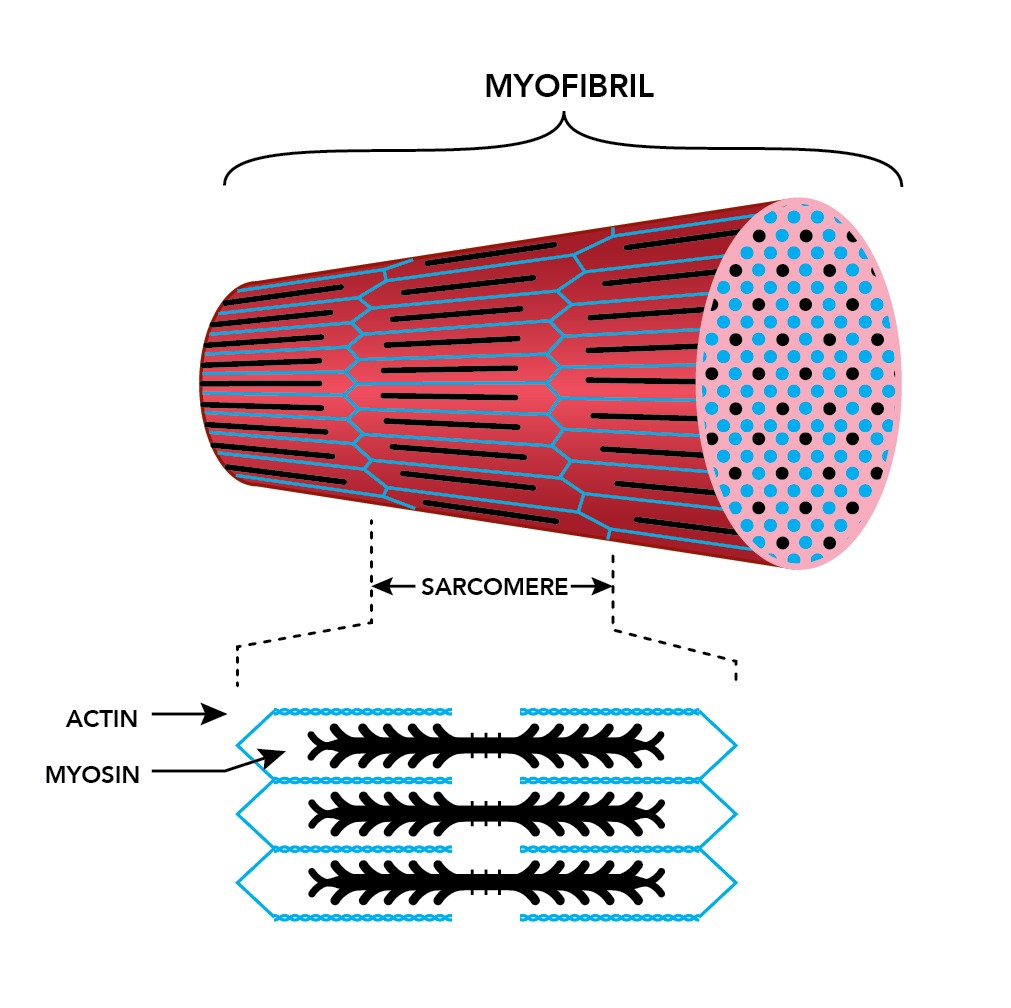

Of all the proteins in meat, myosin and actin are the most important from a cooking perspective. They are the myofibrillar proteins within each sarcomere that affect meat’s texture and moisture-holding capacity. Let’s take a look at how they work together in living muscles:

How Muscle Contraction Works

In the muscles of living animals, the action of the thick filament (myosin) heads attaching and pulling the thin filament (actin) is what causes muscle contraction. The contractile cycle of myosin and actin sliding is what causes skeletal muscle movement.

After slaughter, lack of blood flow to muscle tissue makes it impossible for the contractile cycle to complete its relaxation phase. The actin and myosin irreversibly combine in maximum muscle contraction, or rigor mortis. After rigor mortis, protease-based enzymes (calpain and cathepsin) are fully activated, degrading the meat. This degradation of the myofibrillar network of actomyosin is what tenderizes meat during the aging process.

Denaturation of Myosin and Actin

➤ Myosin: 104-122°F

Actin and myosin play a major role in the changes that take place in meat as it cooks. Myosin begins to denature around 104°F (40°C) with a striking change occurring at 122°F (50°C). Myosin is the thick filament responsible for actively shortening the sarcomere length as it pulls the actin filaments closer together. When myosin denatures it shrinks the sarcomere in diameter. This denaturation changes meat’s texture from raw to being pleasantly cooked and still tender.

➤ Actin: 150-163°F

Actin denatures in a higher temperature range, and this reaction is what is primarily responsible for the toughening of meat fibers and moisture loss in cooked meat. It denatures in the range of 150-163°F (66-73°C). At this point the protein fibers become very firm, shorten in length, and the amount of liquid expelled increases dramatically. Your meat becomes tough and dry when cooked to these higher temperatures. This data accurately supports Kenji’s research on the amount of moisture loss in cooked beef. At 150°F (66°C) the moisture loss doubles from where it is at 120°F (49°C).

Food scientists have determined through empirical research (“total chewing work” and “total texture preference” being my favorite terms) that the optimal texture of cooked meats occurs when they are cooked to 140-153°F/60-67°F, the range in which myosin and collagen will have denatured but actin will remain in its native form. —Cooking for Geeks, Jeff Potter

See the Difference!

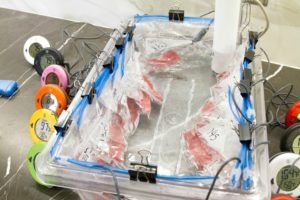

In the image below you can physically see how meat changes as the temperature rises. The meat changes in color, texture, visibly shrinks, and loses moisture. Using New York steaks, we cut them into equally-sized pieces and cooked them to the precise temperatures shown using a sous vide water bath. Changes in meat fiber diameter are visible as early as 115-120°F (46-49°C).

In the image below you can physically see how meat changes as the temperature rises. The meat changes in color, texture, visibly shrinks, and loses moisture. Using New York steaks, we cut them into equally-sized pieces and cooked them to the precise temperatures shown using a sous vide water bath. Changes in meat fiber diameter are visible as early as 115-120°F (46-49°C).

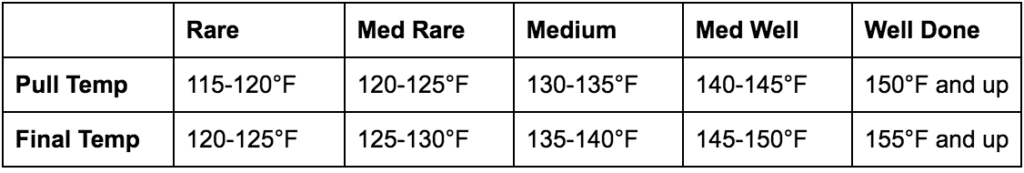

Now understanding what happens to your meat as it cooks, look at the chart of meat doneness temperatures below and see where your personal taste lies. Chances are, you like your steak cooked to a temperature that has allowed the myosin to denature, fats to render, but before the actin begins to denature.

Denatured myosin = yummy; denatured actin = yucky. Dry, overcooked meats aren’t tough because of lack of water inside the meat; they’re tough because on a microscopic level, the actin proteins have denatured and squeezed out liquid in the muscle fibers. —Cooking for Geeks, Jeff Potter

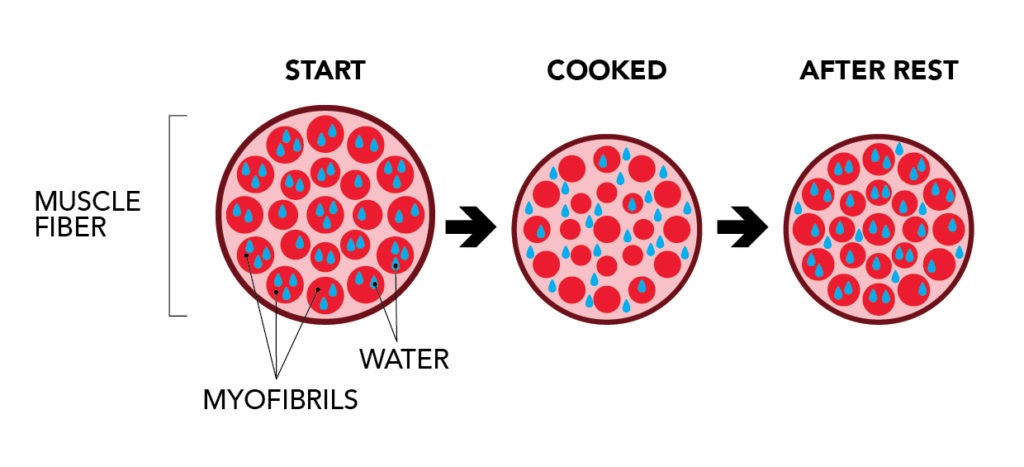

Resting Meat to Partially Reverse Moisture Loss

Protein denaturation that is responsible for causing meat to become firm and dry is partially reversible. Denatured actin cannot be changed, but myosin filaments can relax somewhat. This is evident when meat rests. The coagulated protein is able to reabsorb some of the lost moisture.

This knowledge really is the secret to preparing perfectly cooked meat every single time. Being able to track internal temperatures with precision let you know exactly what’s happening inside your meat as it cooks. Overcooking meat by just a few degrees can truly mean the difference between a juicy steak and one that has become irreversibly tough. Cook with confidence!

Resources:

Cooking For Geeks, Jeff Potter

Cook’s Science, Cook’s Illustrated

On Food and Cooking, Harold McGee

John J Jamison says

This subject was on my mind just this week. Is this same process at work when pulling the meat for shredding? I was wondering when I put a large chuck roast in the crock pot – Although edible – when I took it out – it was not really shreddable – like I was hoping for. How does “doneness” play into pork, beef, chicken for shredding?

Kim says

John,

Great question! What you’re likely running into with a cut like a chuck roast is the connective tissue. The collagen-rich connective tissue needs to break down and dissolve before the meat will be tender enough to shred. If you try shredding as soon as the meat reaches a target internal temperature around maybe 140°F, the connective tissue will still be intact and the meat will appear tough and dry.

The collagen needs time in a higher temperature range in order to dissolve into succulent gelatin. Connective tissue begins to dissolve around 160-170°F. Cook your chuck roast until it reaches an internal temperature of 190-200°F and it will fall apart beautifully.

Happy Cooking!

-Kim

Dan Council says

Thank you for all the important educational information you provide. It’s always a great read on Saturday morning with a cup of coffee.

Kim says

Dan,

Thank you for your comment! Topics like this are what we live for 🙂

-Kim

Lance Levy says

Great article! Love your products and your articles. Thank you and keep up the great work.

Kim says

Lance,

Thank you for your kind words. So glad to hear you’re enjoying our products and content.

-Kim

Jim Anthony says

Well done (not meant to be a Freudian slip).

Kim says

Jim,

LOL! We love meat puns around here. 🙂

So glad you liked the content.

-Kim

Brian McGuire says

Then why is brisket cooked to such a high temperature?

Kim says

Brian,

Most excellent question! The reason for brisket’s high doneness temperature has to do with its high level of connective tissue. The connective tissue is mainly composed of collagen—a triple-helix protein structure. Its denaturation temperature is higher than that of myosin. It begins to unfold in the range of 160-170°F. Your brisket needs time at higher temperatures for the collagen to properly dissolve.

If you pull your brisket around 140°F it’ll still be tough and dry. But giving it the time to gradually reach about 200°F will allow ample time for the connective tissue to dissolve into succulent gelatin. The cool thing about this transformation into gelatin is it’s able to absorb up to 10 times its weight in water. So the moisture that was once lost will be reabsorbed and you have a delicious lip-smacking brisket. I hope this helps.

Happy Cooking,

-Kim

Mike Czechowski says

Good question & good answer! I assume this is also the case with the other common “low & slow” large piece of meat cooked as BBQ – pork shoulder?

Kim says

Mike,

Exactly! That is precisely why we cook meat low and slow. It’s to dissolve connective tissue.

-Kim

Shakeel Ahmed says

Good afternoon,

I know I’m late to the party with this question but hopefully someone knowledgeable can respond.

Can the same process of collagen breakdown into gelatin be achieved, and thus shredded tender brisket, if the piece of meat was kept between 160-170F in a sous vide and searing after to achieve the wonderful maillard reaction for colour and flavour? By not taking the brisket to 200F you will surely reduce the moisture loss based on your above article. Is there another reason we would want to take brisket to the higher temperature to aid in the “fall apart” texture of the meat?

Many thanks,

Shak

Martin says

At 160 you still get the same dry-out as you would at the higher temperatures, the proteins denature and squeeze extra hard starting at 150°F. You could certainly sous vide at 160–170°F, but at those temperatures the time for collagen dissolution will be LONG. Like, 36 hours long.

Lynda Harding says

Very informative. I do have a quibble about the introduction. Evolution doesn’t have a direction. We aren’t more highly evolved than our ancestors. We’re just adapted to a different environment, and our differences from our recent ancestors are likely as much cultural as biological.

Well, there is a theory about the purpose of human evolution — we evolved to invent cars so that dogs could go for a ride.

Meat Eater says

This article claims that resting meat can help recover from moisture loss. Dr. Blonder from Meathead Goldwyn’s BBQ empire has performed experiments to show that resting the meat does absolutely nothing. Could you please resolve this scientific conundrum. Both opinions cannot be true.

Kim says

Thank you, MeatEater for your insightful question. Yes, we have long disagreed with Meathead on the importance of resting meat, as he well knows. We adore Meathead and consider him one of the giants in the field, but we agree to disagree on this topic. And we stand by our own research and the food scientists that we quote. Hope this is helpful.

Thank you,

-Kim

Chris says

I watched a chef on a YouTube channel I enjoy test the idea of resting a New York strip steak. He tested the idea of resting, temp drop and moisture pooling. He cut seven NY’s at 0, 2, 4, 6, 8, 10 and 12 minutes apart, all cooked to 130 degrees. The first right off the grill lost the most liquid. But the rest, from 2-12 minutes was negligible. Then the only difference was temp drop in the meat.

I am sure you have tested this idea. What are your thoughts?

Kim says

Chris,

Such a great observation. Credible experts such as America’s Test Kitchen and Kenji Lopez-Alt have also performed testing on this topic. In Kenji’s article, The Food Lab: The Importance of Resting Meat, He slices into steaks after resting for 0, 2.5, 5, 7.5, 10, and 12.5 minutes. His findings were similar to what you have described. The moisture retention of the steaks for longer than a 5-minute rest was negligible. For a steak, it seems to be most beneficial to let it rest for 2.5 to 5 minutes.

Resting meat is important for retaining moisture, but also to allow carryover cooking to complete. The latent heat on the exterior of the meat will continue to travel to the thermal center of the meat until the temperature equilibrates, and this usually takes about 2-5 minutes in steaks. Meaning, if you pull your steak from the grill at 125°F, its internal temperature will more than likely rise to 130°F while resting.

My thoughts are that resting is important for the eating quality of steaks, but you don’t need to stress about anything more than a 2-5 minute rest.

Thank you for your question!

-Kim

Chris says

Thank you Kim. On another fascinating meat temperature note, I purchased you Smoke Alarm and it is tops in the industry in my opinion. I LOVE that little guy!

On a recent cook of a Tri Tip Santa Maria style with red oak coals, I had an amazing carry over of 18 degrees. It was amazing to watch. And the coolest thing was the Smoke was recording the highest temp on the right side of the main temp reading. Thanks for making something so easy to use and very well built!

Rick Caras says

You got some ‘splaining to do Lucy.

In the temperature charts, you label ranges, but introduce some “no mans land” between them. Whereas for the first two segments, the ranges are contiguous. Yes one person’s “medium-well” is another’s “well done”…but that will always be when we assign “names” to things that are more precise like temperature and temperature ranges.

Why?

What do we call meat cooked at 132.5? Medium-Rare-Medium? kind of like directions, ENE or NNE?

Keep on cookin’ and keep on tracking temperature TW.

http://doxepin.sbol.info says

This web site definitely has all the information and facts I wanted concerning this

subject and didn’t know who to ask.

Denice says

Wonderful article! We are linking to this great post

on our site. Keep up the good writing.